|

General Description

|

|

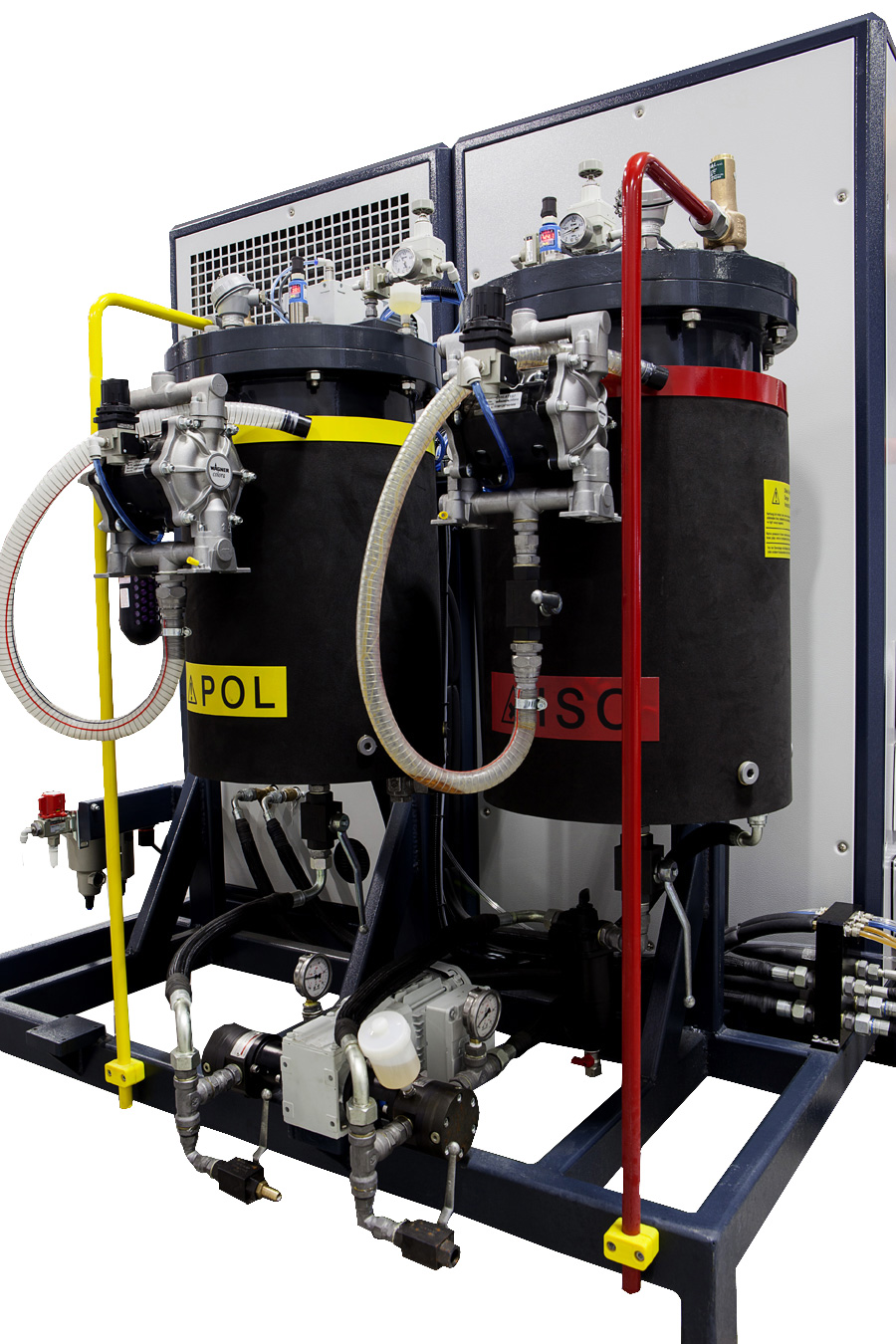

Low pressure mixing and dosing units

|

|

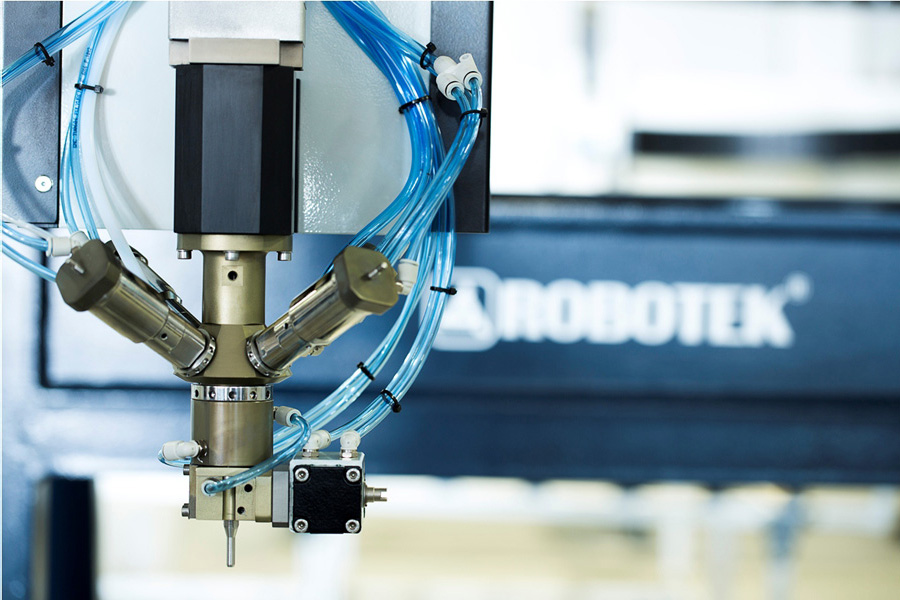

Mixing Head

|

|

High Performance Process Control

The system is equipped with sophisticated process technology that ensures dispensing stability. Ultrasonic type level sensors feedback component levels to the automatic refilling system. High precision regulators control the air pressure of the tanks. Material pressure is detected by pressure sensors and displayed in the user interface and in case the maximum line pressure is reached, the system is programmed to run the automatic cleaning function for the mixing head. Water temperature for the temperature conditioning system is detected and controlled by the temperature conditioning system. Temperature sensors detect the temperature of the materials inside the tanks to ensure that the recommended process temperature is reached. Pressurised tanks are fitted with safety relief valves for the safety aspect of the system. High precision dosing pumps enables the system meter the materials in correct mixing ratio. Recirculation pumps provide that the materials inside the hoses are conditioned according to the process temperature required.

|

|

Environmentally Friendly Recirculating Cleaning System Environmentally friendly recirculating cleaning system is used with biodegradable cleaning agent. The cleaning agent is filtered and waste particles are separated. Rejuvenated cleaning agent recycled and used over and over again. No methylene chloride, no contaminated water is discharged. It is a real and proven alternative to conventional cleaning systems in terms of performance, economy and greatly improved environmental health and safety. |

|

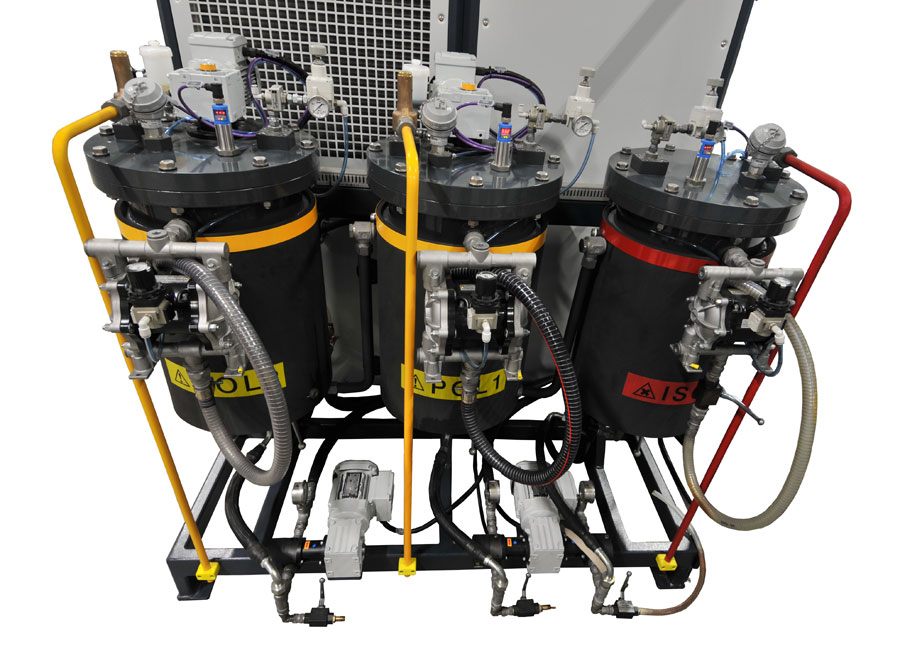

Additional Component Tanks

|

|

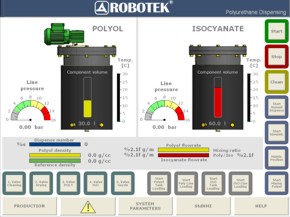

User Interface

|

|

Easy Dispensing Software

|

|

Films of a Formed-in-Place-Foam-Gasket Dispensing Application for Electrical Enclosures Please view examples of a Formed-in-Place-Foam-Gasket - FIPFG - dispensing application for electrical enclosures and air filters shown in the following films.

|

|

Film of a Formed-in-Place-Foam-Gasket Dispensing Application for Drum Lids Please view an example of a Formed-in-Place-Foam-Gasket - FIPFG - dispensing application for drum lids shown in the following film.

Film of Robotic Gluing and Gasketing Lines For Air Filter Production Please view two examples of gluing and gasketing lines for air filter production in the following films.

|

This low pressure mixing and dosing unit is specifically designed to be operated with HS and ECO series three axis cartesian robots. Additional to standard configuration, there are various options available.

DDx12 Technical Features

- Dynamic mixing head with environmentally friendly recirculating cleaning system, no methylene chloride and no contaminated water discharge

- System control is based on a stand-alone powerful industrial CNC unit with linear, circular and helical interpolation. The CNC unit is programmed in G code according to DIN 66025. The system is also equipped with an industrial PC for the purpose of man-machine interface.

- Data transfer via LAN, USB or serial interface

- Operator interface with 15” TFT industrial PC

- Operator friendly, graphics based user interface for monitoring and setting up system parameters easily

- Simplified menu based programming and advanced help to achieve intense programming tasks and set up all process parameters easily

- Easy programming software

- Operator panel language in English, German and Turkish other languages are upon request

- Single walled or double walled (optional) stainless steel pressure tanks for A and B components, 40 litres each

- High tensile steel-reinforced polyamide high pressure component hoses

- All component hoses are thermally isolated and isolation materials are also covered with protection nets

- Speed controlled agitator for A component tank

- Air nucleation for A component tank

- Remote diagnostics and maintenance over the internet for an immediate response to customer service requirements

- Ultrasonic type level sensors for continuous component level measurement

- Anti-dripping nozzle valve system

- Automatic flushing and drying system

- High precision dosing and recirculation pumps

- Recipe management, teach mode programming and simulation mode

- Height adjustable feet and floor-anchoring points

- Teach mode programming

- Simulation mode

- Automatic and manual operating modes

- Multi level operator password protection

- Data transfer via LAN, USB stick or serial interface

- Mixing head spindle motor with speed up to 9000 rpm

- Scratch proof coated mixing head parts

- Precise and reliable dispensing with two stage pumping system

- Thermal insulation for component tanks

- Digital pressure monitoring devices for flow rate and pressure control (continuous measurement)

- High tensile steel-reinforced polyamide high-pressure component hoses

- Temperature conditioning unit with heating and cooling features (optional)

- High precision air pressure regulators

- High capacity air dryer filter

- Self cleaning ISO filter for easy maintenance and increased pump life

- Proved and tested EMERGENCY STOP monitoring and deactivation

- Hardware and software limit switches for securing work space

- Pluggable connectors on the switchgear cabinet

- Guide chains for all cables and tubes

- CanBus connection (ProfiBus optional)

- Extended PLC functions for controls of peripherals

- Easy integration into all available handling systems via digital I/O interface

- Closed loop components flow rate and pressure control

- Material recirculation system

- Accurate overlapping at the start and stop point of the seal contour

- 0.3 to 100g/s dispensing capacity

- Wide working viscosity range from 50 to 200.000 mPa*s (higher viscosities on request)

- Separated valve and mixing section

- Available mixing chambers in different sizes

- Available nozzles in different sizes

- Mixing chamber temperature control

- Short maintenance times

- Limited contact with processed material

- Low maintenance

- High productivity and reliability

This low pressure mixing and dosing unit is specifically designed to be operated with 6 DOF robots. Additional to standard configuration, there are various options available. It is a flexible solution for demanding applications.

DDFx12 Technical Features

- Dynamic mixing head with environmentally friendly recirculating cleaning system, no methylene chloride and no contaminated water discharge

- System control is based on a powerful industrial PLC unit.

- Data transfer via LAN, USB or serial interface

- Operator interface with 15” TFT industrial PC

- Operator friendly, graphics based user interface for monitoring and setting up system parameters easily

- Simplified menu based programming and advanced help to achieve intense programming tasks and set up all process parameters easily

- Easy programming software

- Operator panel language in English, German and Turkish other languages are upon request

- Single walled or double walled (optional) stainless steel pressure tanks for A and B components, 40 litres each

- High tensile steel-reinforced polyamide high pressure component hoses

- All component hoses are thermally isolated and isolation materials are also covered with protection nets

- Speed controlled agitator for A component tank

- Air nucleation for A component tank

- Remote diagnostics and maintenance over the internet for an immediate response to customer service requirements

- Ultrasonic type level sensors for continuous component level measurement

- Anti-dripping nozzle valve system

- Automatic flushing and drying system

- High precision dosing and recirculation pumps

- Recipe management, teach mode programming and simulation mode

- Height adjustable feet and floor-anchoring points

- Teach mode programming

- Simulation mode

- Automatic and manual operating modes

- Multi level operator password protection

- Data transfer via LAN, USB stick or serial interface

- Mixing head spindle motor with speed up to 9000 rpm

- Scratch proof coated mixing head parts

- Precise and reliable dispensing with two stage pumping system

- Thermal insulation for component tanks

- Digital pressure monitoring devices for flow rate and pressure control (continuous measurement)

- High tensile steel-reinforced polyamide high-pressure component hoses

- Temperature conditioning unit with heating and cooling features (optional)

- High precision air pressure regulators

- High capacity air dryer filter

- Self cleaning ISO filter for easy maintenance and increased pump life

- Proved and tested EMERGENCY STOP monitoring and deactivation

- Hardware and software limit switches for securing work space

- Pluggable connectors on the switchgear cabinet

- Guide chains for all cables and tubes

- CanBus connection (ProfiBus optional)

- Extended PLC functions for controls of peripherals

- Easy integration into all available handling systems via digital I/O interface

- Closed loop components flow rate and pressure control

- Material recirculation system

- Accurate overlapping at the start and stop point of the seal contour

- 0.3 to 100g/s dispensing capacity

- Wide working viscosity range from 50 to 200.000 mPa*s (higher viscosities on request)

- Separated valve and mixing section

- Available mixing chambers in different sizes

- Available nozzles in different sizes

- Mixing chamber temperature control

- Short maintenance times

- Limited contact with processed material

- Low maintenance

- High productivity and reliability

Automatic Refilling Solutions

With automatic refilling, there is no need to open the cover of the tanks for manual refilling. Compared to manual refilling, it is an advantage to prevent the exposure or contamination of the component being filled. Also, any risk of damages due to opening of tank covers, such as damages to the components installed on the cover of tanks and damages resulting from opening of pressurized tanks are prevented. In our option package, we offer two types of automatic refilling solutions.

Embedded automatic refilling system

One of the refilling solutions we offer is the embedded automatic refilling system. It is an ideal solution for companies such as electrical enclosure manufacturers, having low production rates and looking for an economical and as well as environmentally friendly solution against manual refilling.

Automatic supply station

Our second refilling solution is the automatic supply station to refill from barrels, drums and IBC tanks. It is especially suitable for companies operating in demanding industries with high production rates such as automotive and household appliances. With this option, in such processes, there will be no interruption caused by manual refilling. Low pressure mixing and dosing unit loads components automatically from the stations when the levels decrease lower than preset value in the tanks

Temperature Conditioning System Optimal polyurethane chemical reaction is achieved under room temperature conditions. If there is no suitable ambient temperature at the production area, we offer temperature conditioning system with heating and cooling features. It ensures that the temperature of components in the tanks and mixing head meet the process requirement.

Installation of additional component tanks and the relevant process equipment

In case the system is intended to be used for combined processes such as dispensing of thixotropic gasket for flat/inclined surfaces and liquid gasket for grooves or a gasket material and an adhesive or an adhesive and a potting product, our option package includes installation of additional component tanks and the relevant process equipment. This also enables to use one dispensing system for multiple purposes of sealing, bonding and potting/encapsulation on the same work piece.

Other options

- Mixing chambers with different volumes

- Nozzles in different sizes

- Electrically actuated stirrer on polyol barrel/drum for pre homogenisation

- Nucleation controller for density control of foam materials

- Coloured seal

- More options on request

MH2C07 low pressure dynamics mixing head

MH2C07 is a high precision dynamic mixing head with temperature control is designed for 2or 3 components (optional). Material components being dosed in the mixing head arealways homogeneous and equally conditioned in correct mixing ratio. Mixinghead is equipped with anti-dripping nozzle valve.

It is a compact, low pressure dynamic mixing system for precise meter, mix and dispensing for liquid to high viscous polymeric reactive materials. Flexibility of the mixing head makes it suitable for dispensing of complex parts and applications. Modular design and the consequent separation of valve group and mixing chamber make the MH2C07 maintenance friendly. The mixing head is equipped with two pneumatic actuated needle seat valves for materials, a flushing and a blowing valve. The mixer and the mixing chamber are made of stainless steel. Tungsten Carbide axial face seal isolates the mixing chamber and the mixer shaft. All mixing chambers have cooling and heating systems for stabilizing the temperature.

Mixing head output capacity ranges, regulated by the respective configuration of pumps from 0.3 to 100 g/s with a dosing accuracy of +/– 1%, thus covering a wide field of applications. The stirrer speed can be electronically adjusted between 0-9000 rpm to optimize the production process. Specific stirrer design, environmentally friendly recirculating cleaning system and the maintenance free anti-drip nozzle shut-off device makes up for perfect construction.

Static mixing head

Static mixing head is equipped with valves and a static mixer. Depending on process requirements, the number of valves increases and the static mixer size changes. Components encounter at the valve outlets and mixed in the static mixer. Disposable static mixers used in dispensing systems without solvent cleaning are discarded after a period of use.

The robotic dispensing system is a sealing, bonding and potting/encapsulation solution for electrical enclosures, automotive parts, air filters, luminaries, drum lids, electronic components and many more. The standard configuration includes a low pressure mixing and dosing unit, cartesian or 6 DOF robot, a dispensing table and a temperature conditioning unit. There are wide range of options and automation solutions available to configure the ideal solution for your applications.

The robotic dispensing system is a sealing, bonding and potting/encapsulation solution for electrical enclosures, automotive parts, air filters, luminaries, drum lids, electronic components and many more. The standard configuration includes a low pressure mixing and dosing unit, cartesian or 6 DOF robot, a dispensing table and a temperature conditioning unit. There are wide range of options and automation solutions available to configure the ideal solution for your applications. Common base frame for the control panel and low pressure mixing and dosing unit and temperature conditioning unit being embedded into the control panel provides a compact design. It is equipped with stainless steel, temperature controlled (optional), double walled (optional) and thermally isolated pressurised tanks. Temperature conditioning system (optional) with heating and cooling features ensures that the temperature of components in the pressurised tanks and mixing head meet the process requirements. A component is mixed with air (nucleation) and stirred to homogenization in the pressurised tanks. High precision and speed controlled metering and recirculation pumps are installed to convey material components from pressurized tanks to the mixing head. Ultrasonic type level sensors feedback component levels to the automatic refilling system. Automatic refilling solutions (optional) prevent exposure or contamination of the component being refilled. All component hoses in the system are thermally isolated and isolation materials are also covered with protection nets.

Common base frame for the control panel and low pressure mixing and dosing unit and temperature conditioning unit being embedded into the control panel provides a compact design. It is equipped with stainless steel, temperature controlled (optional), double walled (optional) and thermally isolated pressurised tanks. Temperature conditioning system (optional) with heating and cooling features ensures that the temperature of components in the pressurised tanks and mixing head meet the process requirements. A component is mixed with air (nucleation) and stirred to homogenization in the pressurised tanks. High precision and speed controlled metering and recirculation pumps are installed to convey material components from pressurized tanks to the mixing head. Ultrasonic type level sensors feedback component levels to the automatic refilling system. Automatic refilling solutions (optional) prevent exposure or contamination of the component being refilled. All component hoses in the system are thermally isolated and isolation materials are also covered with protection nets. One component or multi component, we configure our dispensing solutions with a suitable one-component-dispenser or a multi-component-dynamic or static-mixing head based on application requirements. A dynamic mixing head composes of valves, mixing chamber, mixer and anti-dripping nozzle valve system. Dynamic mixer rotates in the mixing chamber with controlled speed. The temperature of the mixing head is stabilised with the heating and cooling function of the temperature conditioning system. The materials mixed and dispensed with a dynamic mixing head are always homogeneous and equally conditioned in correct mixing ratio. A static mixing head composes of valves and a disposable static mixer.

One component or multi component, we configure our dispensing solutions with a suitable one-component-dispenser or a multi-component-dynamic or static-mixing head based on application requirements. A dynamic mixing head composes of valves, mixing chamber, mixer and anti-dripping nozzle valve system. Dynamic mixer rotates in the mixing chamber with controlled speed. The temperature of the mixing head is stabilised with the heating and cooling function of the temperature conditioning system. The materials mixed and dispensed with a dynamic mixing head are always homogeneous and equally conditioned in correct mixing ratio. A static mixing head composes of valves and a disposable static mixer.  Additional component tanks can be installed to combine two or more of production processes such as sealing, bonding and potting/encapsulation to configure one dispensing system for multiple purposes for the same work piece. It is possible to combine processes such as dispensing of thixotropic gasket for flat/inclined surfaces and liquid gasket for grooves or a gasket material and an adhesive or an adhesive and a potting product. The modularly extendable design enables the third tank and the relevant process equipment to be installed later into an existing system. This provides our customers greater flexibility in terms of production planning and budgeting.

Additional component tanks can be installed to combine two or more of production processes such as sealing, bonding and potting/encapsulation to configure one dispensing system for multiple purposes for the same work piece. It is possible to combine processes such as dispensing of thixotropic gasket for flat/inclined surfaces and liquid gasket for grooves or a gasket material and an adhesive or an adhesive and a potting product. The modularly extendable design enables the third tank and the relevant process equipment to be installed later into an existing system. This provides our customers greater flexibility in terms of production planning and budgeting.  The system has operator friendly, graphics based user interface for monitoring and setting up system parameters easily. The user interface incorporates dynamic icons for component levels, temperatures and line pressures; bars for dispense number, components’ flow rate and mixing ratio; buttons for system control, system diagnostics interface, menu based programming interface, CNC HMI interface and advanced help interface.

The system has operator friendly, graphics based user interface for monitoring and setting up system parameters easily. The user interface incorporates dynamic icons for component levels, temperatures and line pressures; bars for dispense number, components’ flow rate and mixing ratio; buttons for system control, system diagnostics interface, menu based programming interface, CNC HMI interface and advanced help interface. Easy dispensing software for rectangular or circular paths is included as a standard feature and especially suitable for manufacturers having products with various ranges of dimensions. Special dispensing software offers great flexibility and reduces system programming and setup time dramatically. Operator fills in dispensing data on "dispensing set-up-page” in a couple of minutes and the software generates the necessary G codes automatically.

Easy dispensing software for rectangular or circular paths is included as a standard feature and especially suitable for manufacturers having products with various ranges of dimensions. Special dispensing software offers great flexibility and reduces system programming and setup time dramatically. Operator fills in dispensing data on "dispensing set-up-page” in a couple of minutes and the software generates the necessary G codes automatically.