|

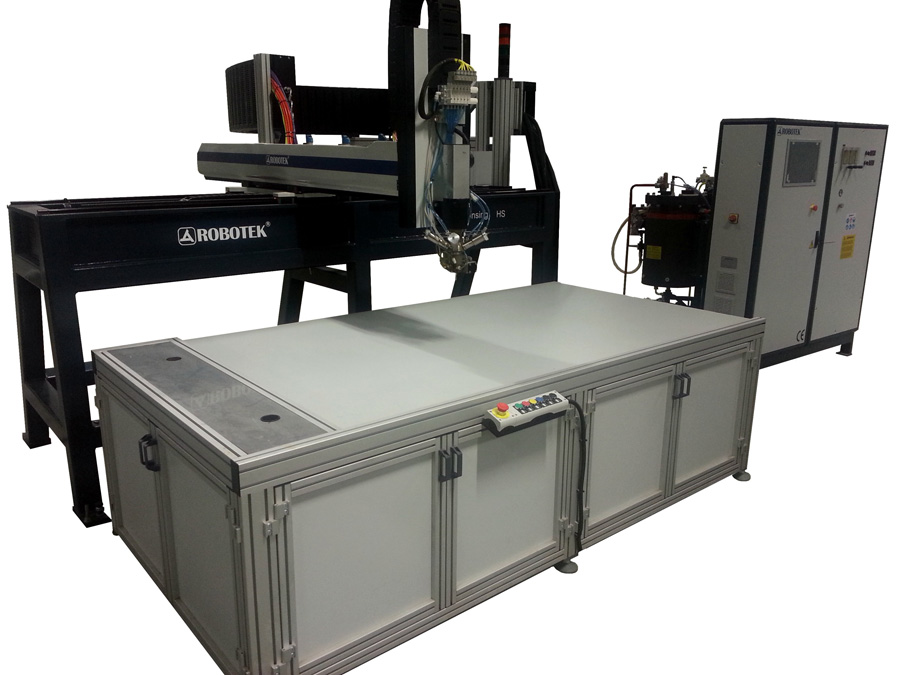

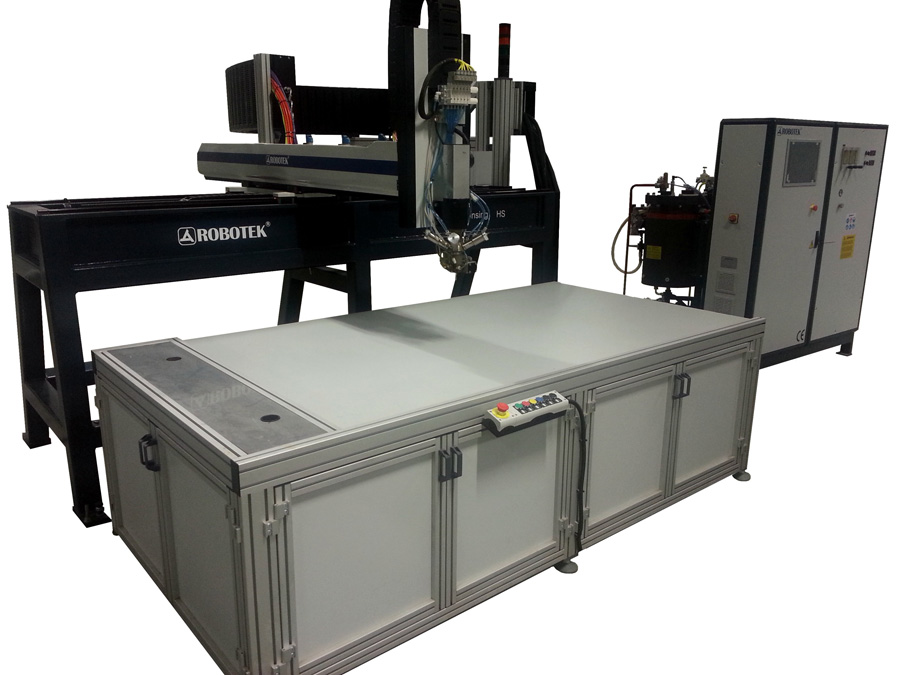

HS Series Cartesian Robot

HS series robot is designed especially for high speed and precise three dimensional dispensing of sealants, glues or encapsulants. Robust steel frame construction with high dynamics servo motors, low backlash gearboxes and high precision tooth & rack drives on all axes provide high acceleration rates, high traversing speeds and precise contour tracking. The state-of–the-art design concept ensures to achieve shorter process time, smooth and precise dispensing. HS series robot is designed especially for high speed and precise three dimensional dispensing of sealants, glues or encapsulants. Robust steel frame construction with high dynamics servo motors, low backlash gearboxes and high precision tooth & rack drives on all axes provide high acceleration rates, high traversing speeds and precise contour tracking. The state-of–the-art design concept ensures to achieve shorter process time, smooth and precise dispensing.

The system control is based on a stand-alone powerful industrial CNC unit with linear, circular and helical interpolation. The CNC unit is programmed in G code according to DIN 66025 and special dispensing software for enclosure cabinets is also available. The system has an operator friendly interface with 15’’ TFT industrial PC for simplified menu based programming. Menu based programming and advanced help pages enable to achieve intense programming tasks and set up all of the process parameters easily. System has remote diagnostics and maintenance function over the internet for an immediate response to customer service requirements.

HS Series Cartesian Robot Technical Values

-

Electrical design: According to EN60204-1 and EN60439-1

-

Mains connection: 3x400 V AC, 50/60 Hz

-

Rated power approx.: 10kVA

-

Compressed air approx.: 1,5 l/m @6-7 bar

-

Manipulator: Robust, steel construction 3 degree of freedom cartesian robot

-

Maximum axis speed: 60 m/min

-

Maximum acceleration: 8 m/s²

-

Displacements: X=2250mm, Y=1250mm, Z=300mm

-

Positioning accuracy (X,Y,Z): +/- 50 µm (ISO 9283 standardınagöre)

-

Repeatability (X,Y,Z):+/- 50 µm (ISO 9283 standardınagöre)

-

Mixing ratio: infinitely adjustable

-

Dosing: 2 high precision pumps for dosing, 2 pumps for recirculation

-

Output quantity: 0.3-100g/s

|

|

ECO Series Cartesian Robot

ECO robot is a cost-effective solution especially for high speed and precise three dimensional dispensing of sealants, glues or encapsulants. System mechanics consist of maintenance-free ball circulating linear guides for extended life time, timing belt linear motion modules for high speed and high acceleration/deceleration rates, maintenance free servo motors and precision gearboxes. ECO robot is a cost-effective solution especially for high speed and precise three dimensional dispensing of sealants, glues or encapsulants. System mechanics consist of maintenance-free ball circulating linear guides for extended life time, timing belt linear motion modules for high speed and high acceleration/deceleration rates, maintenance free servo motors and precision gearboxes.

The system control is based on a stand-alone powerful industrial CNC unit with linear, circular and helical interpolation. The CNC unit is programmed in G code according to DIN 66025 and special dispensing software for enclosure cabinets is also available. The system has an operator friendly interface with 15’’ TFT industrial PC for simplified menu based programming. Menu based programming and advanced help pages enable to achieve intense programming tasks and set up all of the process parameters easily. System has remote diagnostics and maintenance function over the internet for an immediate response to customer service requirements.

ECO Series Cartesian Robot Technical Values

-

Electrical design: According to EN60204-1

-

Mains connection: 3x400 V AC, 50/60 Hz

-

Rated power approx.: 9kVA

-

Compressed air approx.: 1,5 l/m @6-7 bar

-

Manipulator: 3 degree of freedom cartesian robot constructed by aluminium profiles

-

Maximum axis speed: 30 m/min

-

Maximum acceleration: 2 m/s²

-

Displacements: X=2250mm, Y=1250mm, Z=300mm

-

Positioning accuracy (X,Y,Z): +/-0.25

-

Repeatability (X,Y,Z): +/-0.25mm

-

Mixing ratio: infinitely adjustable

-

Dosing: 2 high precision pumps for dosing

-

Output quantity: 5-100g/s

|

|

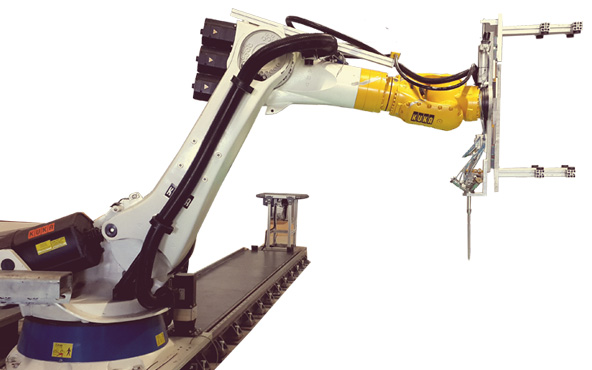

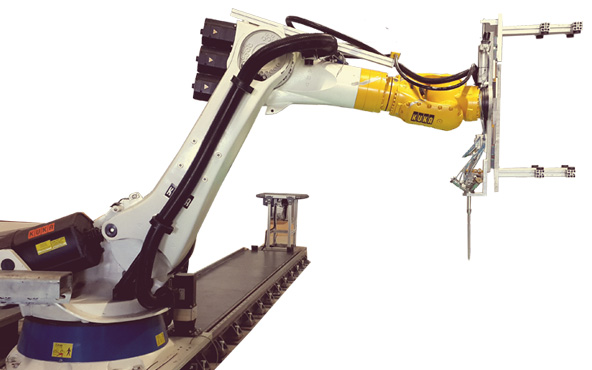

6DOF Robots

Six degree of freedom robots are possible to be integrated in our dispensing solution. 6 DOF robots offer many advantages for production processes requiring more flexible approach. Our design engineers evaluate your production requirements and configure the most suitable solution. In dispensing applications perspective, 6 DOF robots are especially suitable for Six degree of freedom robots are possible to be integrated in our dispensing solution. 6 DOF robots offer many advantages for production processes requiring more flexible approach. Our design engineers evaluate your production requirements and configure the most suitable solution. In dispensing applications perspective, 6 DOF robots are especially suitable for

-

dispensing on complicated 3D and complex contours

-

dispensing on different sides of the same workpart

-

designing more compact workcells

-

turning and moving the workpart under the nozzle of a stationary mixing head to facilitate dispensing on the required sides and paths of a work part.

-

programming one robot to facilitate multi purposes operations additional to dispensing such as loading, unloading, positioning and turning the workpart to enable dispensing on the required sides and paths of a workpart.

|

HS series robot is designed especially for high speed and precise three dimensional dispensing of sealants, glues or encapsulants. Robust steel frame construction with high dynamics servo motors, low backlash gearboxes and high precision tooth & rack drives on all axes provide high acceleration rates, high traversing speeds and precise contour tracking. The state-of–the-art design concept ensures to achieve shorter process time, smooth and precise dispensing.

HS series robot is designed especially for high speed and precise three dimensional dispensing of sealants, glues or encapsulants. Robust steel frame construction with high dynamics servo motors, low backlash gearboxes and high precision tooth & rack drives on all axes provide high acceleration rates, high traversing speeds and precise contour tracking. The state-of–the-art design concept ensures to achieve shorter process time, smooth and precise dispensing. ECO robot is a cost-effective solution especially for high speed and precise three dimensional dispensing of sealants, glues or encapsulants. System mechanics consist of maintenance-free ball circulating linear guides for extended life time, timing belt linear motion modules for high speed and high acceleration/deceleration rates, maintenance free servo motors and precision gearboxes.

ECO robot is a cost-effective solution especially for high speed and precise three dimensional dispensing of sealants, glues or encapsulants. System mechanics consist of maintenance-free ball circulating linear guides for extended life time, timing belt linear motion modules for high speed and high acceleration/deceleration rates, maintenance free servo motors and precision gearboxes. Six degree of freedom robots are possible to be integrated in our dispensing solution. 6 DOF robots offer many advantages for production processes requiring more flexible approach. Our design engineers evaluate your production requirements and configure the most suitable solution. In dispensing applications perspective, 6 DOF robots are especially suitable for

Six degree of freedom robots are possible to be integrated in our dispensing solution. 6 DOF robots offer many advantages for production processes requiring more flexible approach. Our design engineers evaluate your production requirements and configure the most suitable solution. In dispensing applications perspective, 6 DOF robots are especially suitable for