Complementary Automation Solutions

Our deep knowledge and extensive industrial experience in the fields of Robotics and Motion Techniques enable us to support our customers with complementary automation solutions. Our systems aim to minimise floor space usage, increase throughput, efficiency and productivity and provide possibility to be integrated into existing production lines. From an individual dispensing machine up to fully automated robot cells or turn-key integrated production lines, a broad line of automation solutions is available to meet your production goals.

View some examples of our automation solutions below

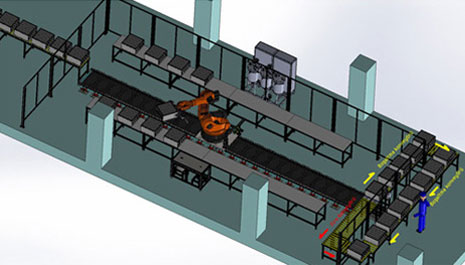

Fully Automated Robotic Cell For Filter Paper Gluing Application

The solution consists of 3 components low pressure dosing and dispensing unit, 6 degrees of freedom robot with 150 kg payload, an end-effector (gripper) designed according to various types of air filters, a carrier axis to move the 6 DOF robot and dozing and dispensing machine, 2 fixed dispensing tables, 2 belt conveyors for loading and unloading, a weighing conveyor for the filters and safety barrier of the robotic cell.

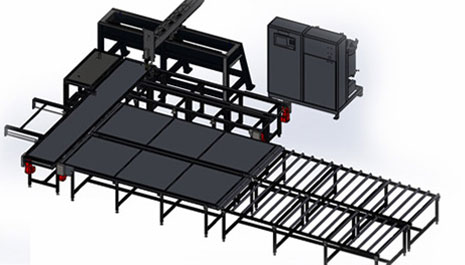

Polyurethane dispensing system with conveyors and curing lines for drum lids production

The solution consists of 2 components low pressure dosing and dispensing unit, 3 degree of freedom cartesian robot, dispensing conveyors, staker and curing conveyors.

Our complementary automation solutions also include

- Turn tables

- Shuttle tables

- Conveyors

- Lift systems

- Work piece storage systems

- Multi-storey waiting systems for drying and curing lines

- Linear storage unit

- Rotary storage unit

- Screw conveyors

- Work piece locating systems

- Work-piece fixtures

- Vacuum clamps

- Work piece grippers

- Vacuum suction plates

- Assembly lines

- Indexing systems

- Linear transfer machines

- Integrated pattern recognition

- Robot cells

- Turn-key integrated production lines

Advanced Tools and Software

Robotek utilizes advance software tools to aid in the concept, design and execution of dispensing automation solutions. Our in-house mechanical, electrical and electronic manufacturing and software development ability provide greater flexibility and fast response to our customers’ requirements. The multi-disciplinary team of engineers collaborate with our customers to tailor projects to the specific requirements of wide range of industrial applications.

The mechanical engineering team use 3D modelling software and simulation tools to design and implement all of the mechanical functions related to our dispensing solutions. This includes overall layout, pneumatics, process equipment, grippers and fixtures. The electrical engineering team is responsible to design electrical layouts, drawings and wiring diagrams. The control engineering team composed of electronic engineers is responsible to program PLCs, HMIs, robots, servo systems and vision systems.

Project Management

Each project is assigned to a project manager and coordinated through the Project Manager. With our systematic way of working, it is guaranteed that all our projects are well-organised and executed to the highest level of performance and eventually all requirements and resources are optimised to meet the customer’s schedule and delivery needs.

Enquiries

For tailor made turn-key automation solutions and complex production systems please contact our sales department.